June 2015 Update, finish line in site!

Gentlemen,

The pace of the Mk II project has been accelerated recently, and I have set

a goal of completing & shipping these by the end of this year.

All motor housings, endcaps & brush tubes have been cut to final dimensions.

The integral rear axle tubes have been reamed to size and armature bushings

line-bored.

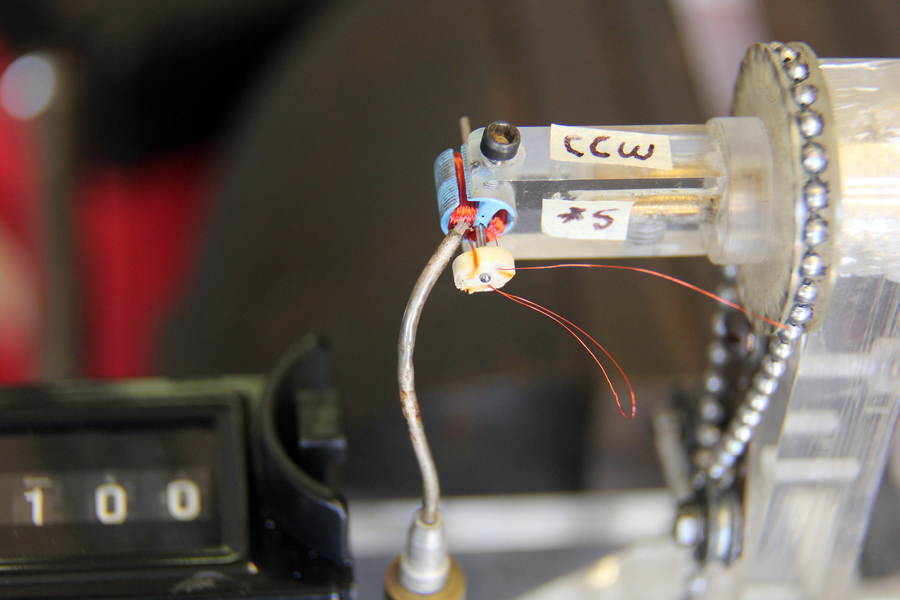

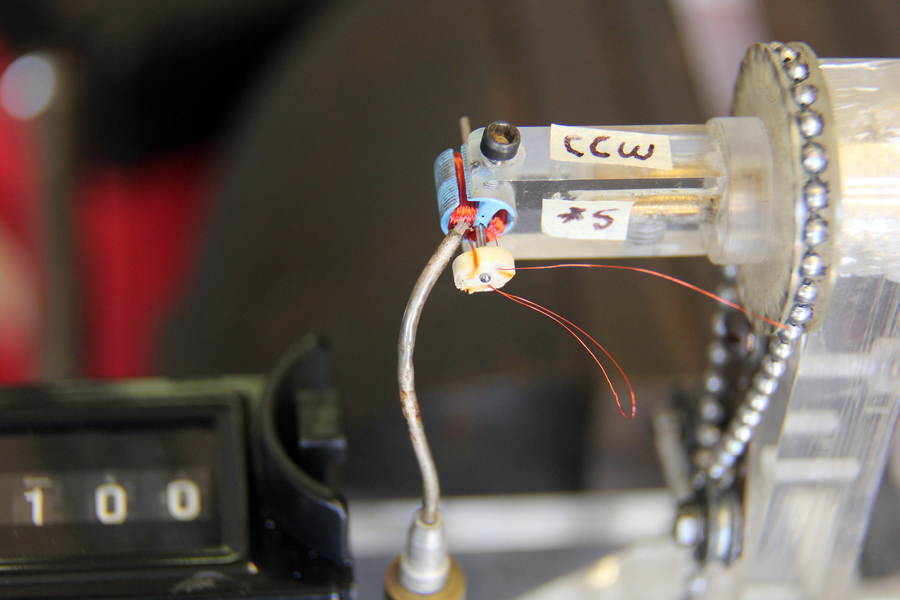

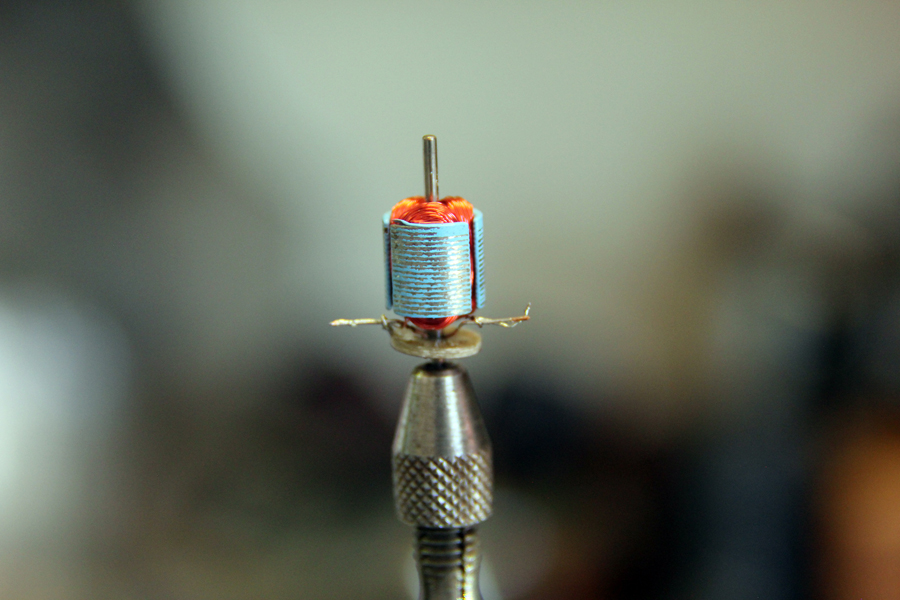

The prototype motor has been completely assembled using the latest rev parts and is running very well!

Moving forward, I have made good use of the various jigs& fixtures, which

has allowed assemblies to be built somewhat rapidly and with consistency.

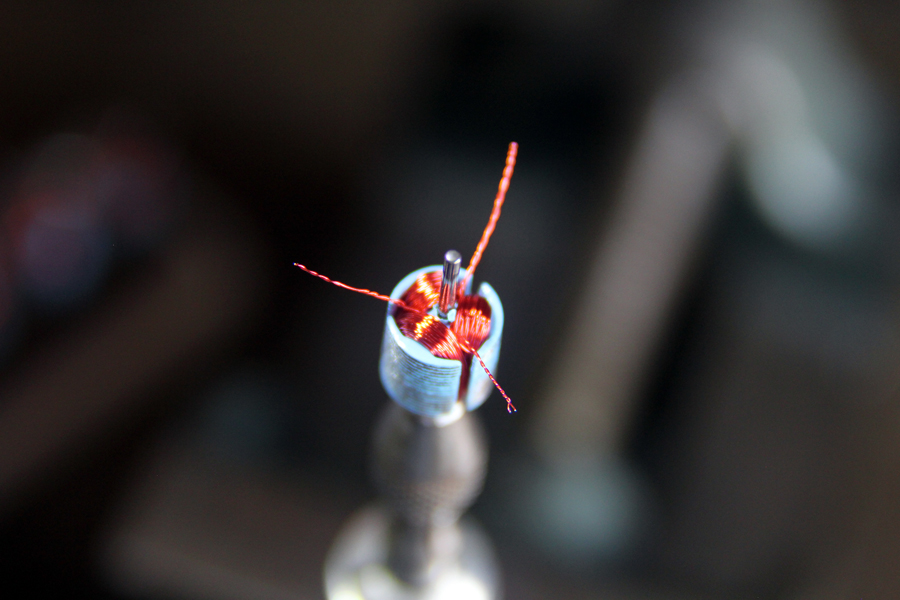

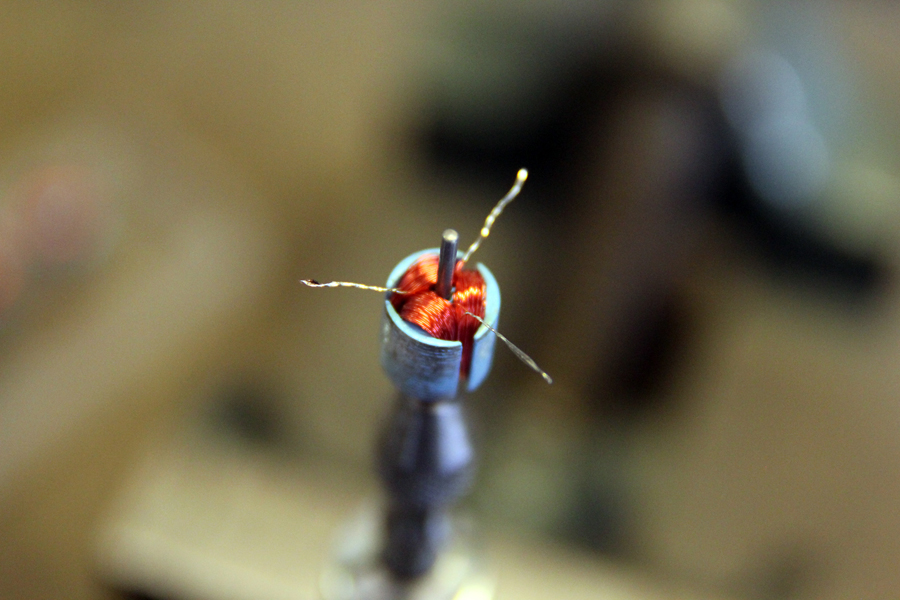

The armature winder has worked quite well and all armatures (13 + 1 spare) are

complete.

I built some small, simple tools to dress the leads – to maintain proper sequence and keep the end winds snug.

Leads carefully tinned for attaching to commutator jumpers.

Soldering the windings to the comm. jumpers was the second most difficult soldering operation – soldering the jumpers to the comm. remaining the toughest.

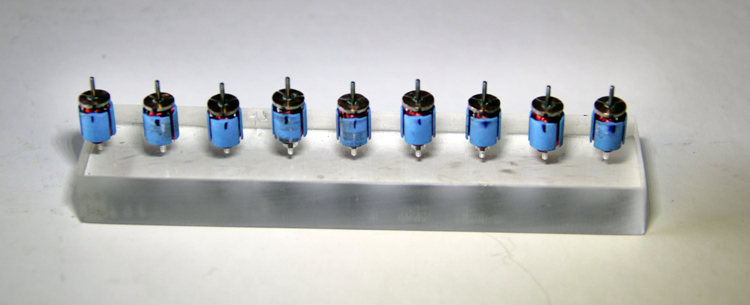

Everybody degreased and ready for epoxy:

You may note that there are only 9 armatures in this photo – 5 additional

units have already been epoxied.

Next step for the armatures is to grind the OD and balance before final assembly

in motors.

STAY TUNED!

(back

to progress page)