Chassis Work by Tony Kurdzuk

Here are pictures and commentary by Tony Kurdzuk. He races at NJ Hobby in Scotch

Plains New Jersey...

June 2009 (latest on top)

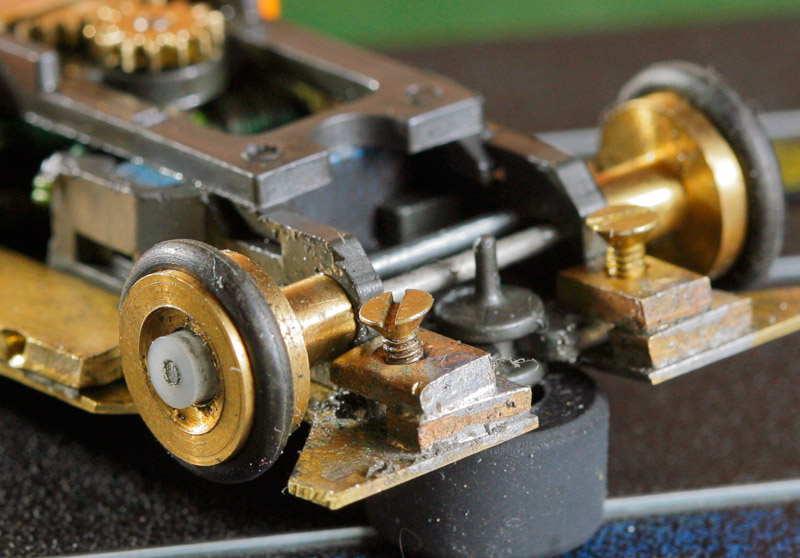

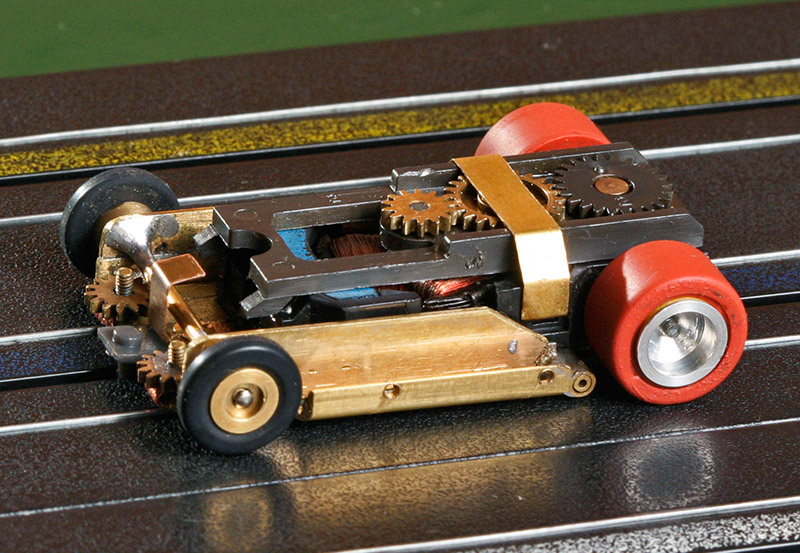

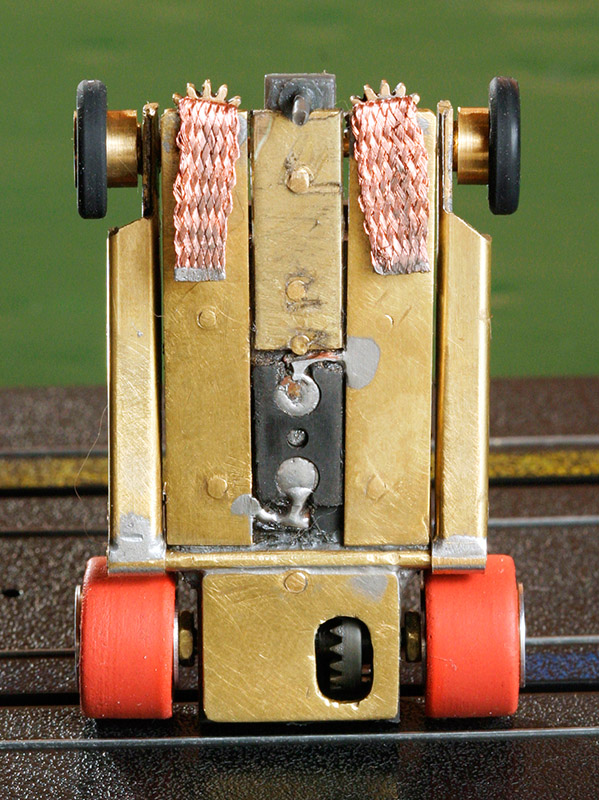

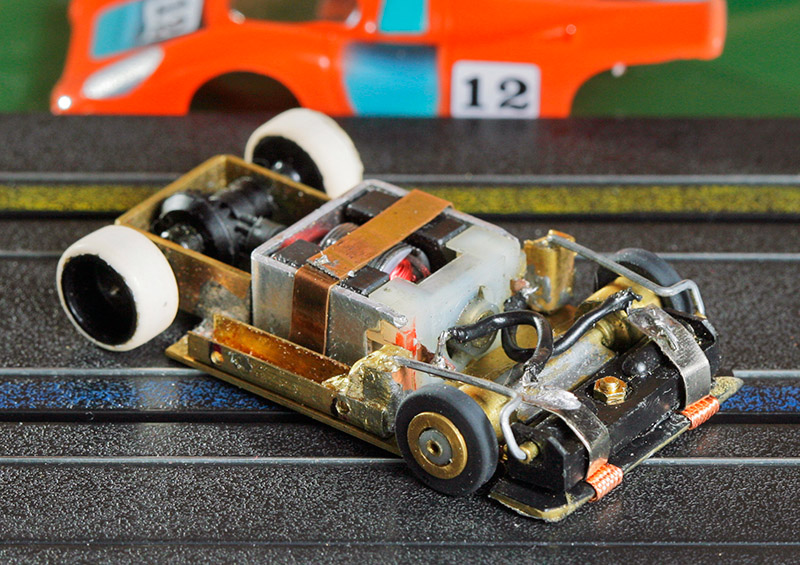

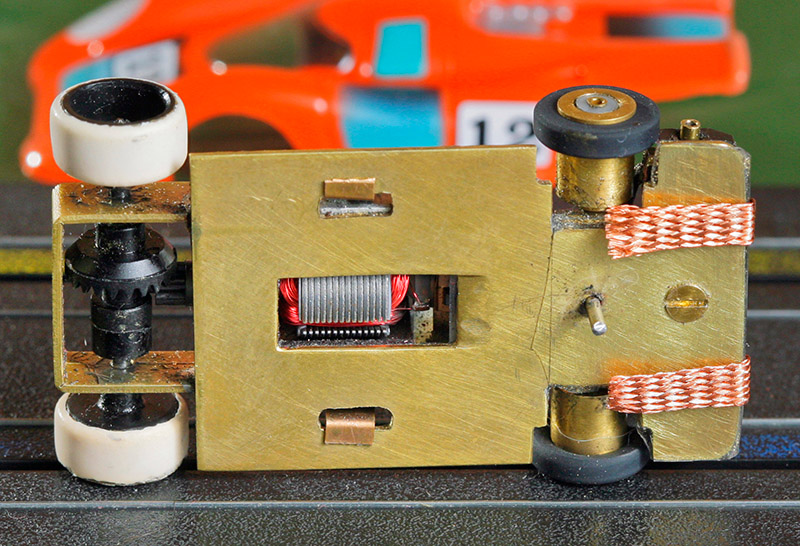

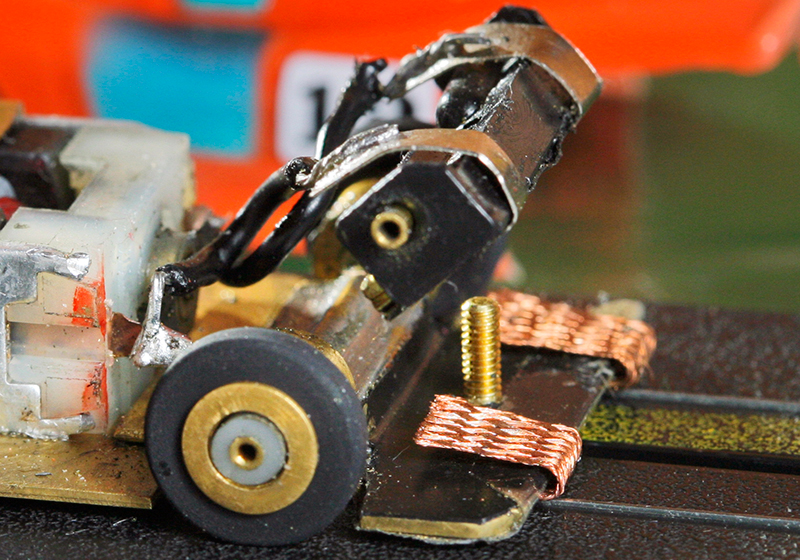

AFX Beedle inspired Drop Arm

This is based on an original Gary Beedle AFX drop arm design from the 70's.

I found some technical CAD drawings of it on scratchbuilt.com

and

figured I'd give it a go. My version is slightly different from the original,

but the premise is the same. For a while I've had an AFX

Super II chassis that someone had badly hogged out the front axle holes on,

and never found a use for it up to now. I chopped off the front and

filed down the bottom leaving just a small area around the brush cups. Beneath

the rear axle is a small pan with a short length of brass tubing

soldered on that acts as the fulcrum for the chassis to rotate on. From there

the "arms" that hold the front axle were made from pieces of .025

"u" shaped and flat brass, with larger brass tubing soldered on the

back ends for hinges. The front axle is brass tubing soldered in for

strength with JW brass Tuff-Ones wheels cut down to proper width and held in

with pins. The pan is made from three separate pieces of .025

brass stock The outer pans are shunted to each of the chassis brush tubes and

have braided pickups attached to their fronts by #72 brass

studs and tapped 14 tooth t-jet gears as lock nuts (the gear teeth make it easy

to loosen and tighten with a fingernail). The center pan has a

standard t-jet guide pin held on by a #72 screw which also holds a hook made

from a t-jet body clip that keeps the front end from rising too

high. I've put in an original AFX quadralam arm with silver brushes, JL magnets,

Super II crown gear, and to keep the "old school" flavor,

original AJ's aluminum rear wheels with AJ's red silicones. I went into this

build thinking it was pretty straight forward, but it turned out to

be much more complicated and involved than I expected. Hats off to Gary for

coming up with the original design. It runs very smooth with great

handling and, with the quadralam, it's very fast. My final step is finding a

suitable body that will allow the front end to move properly

while running.

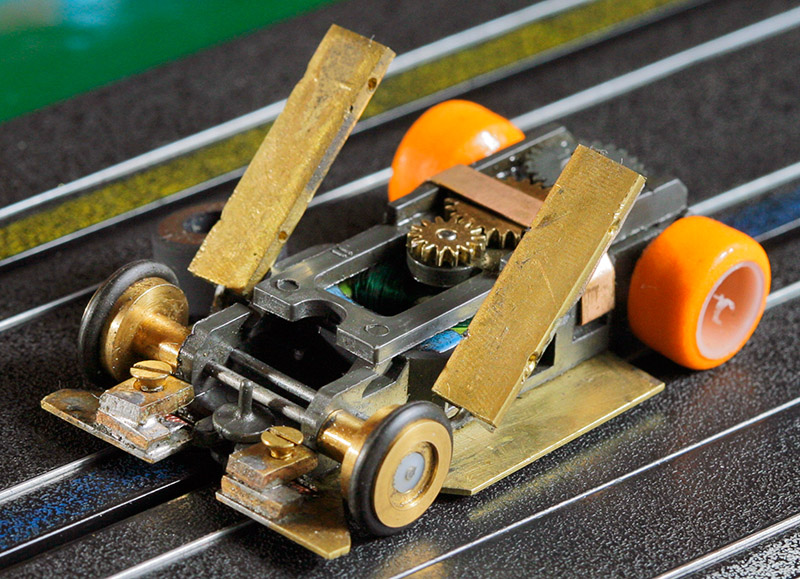

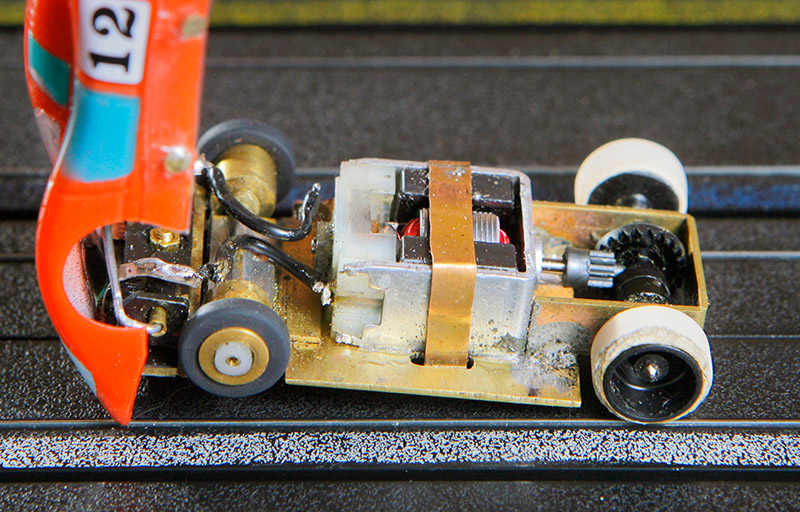

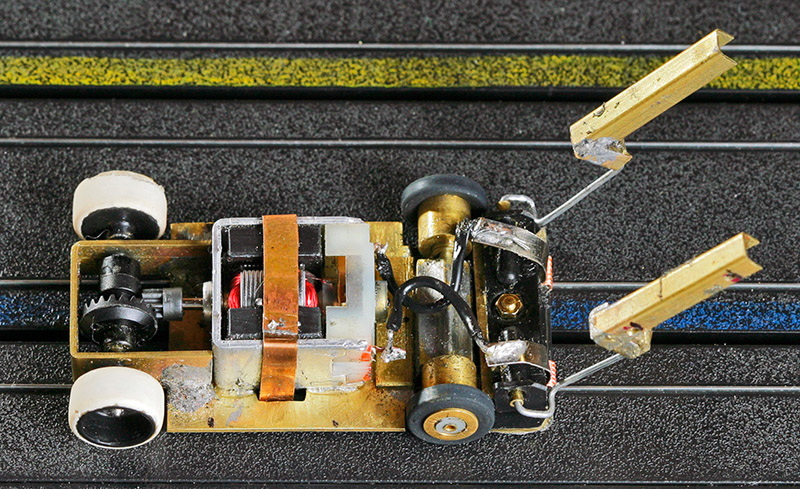

Scratchbuilt in line...

(note---revisions made to this chassis---)

I decided to step up my scratch in line a bit and install a BSRT 35-gauge

"Spinner" arm in the stock Tomy can. I'd heard these arms are

fast from some of the magnet car racers I know but am shocked at how fast. At

1.6 ohms and balanced this arm is a real monster. Instantly

my new problem became lack of traction. Even at 12 volts the rear wheels were

spinning for a good 2 feet out of a curve and chewing up the

AST tires. To help mitigate this I replaced the stock Turbo 22 tooth crown gear

with a Super-G+ 25 tooth gear (I had to re-fashion the rear

axle assembly to allow for the larger gear). It helped but there was still a

lot of wheel spin. For more traction I soldered four pieces of

.065 brass stock (two on each side) about 15mm long into the body mount arms.

The whole thing now comes in at a hefty 40 grams, but the motor

can certainly handle it and the extra weight really improved the handling. There

is still a bit of wheel spin, so I'm a swap-out of the

the 25 tooth crown gear with a 27 tooth Wizzard will take care of it.

pics with revisions.....

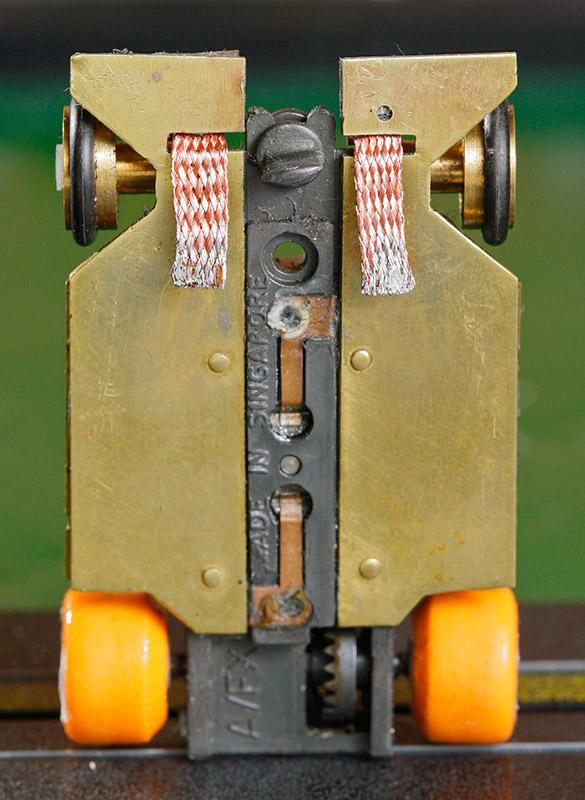

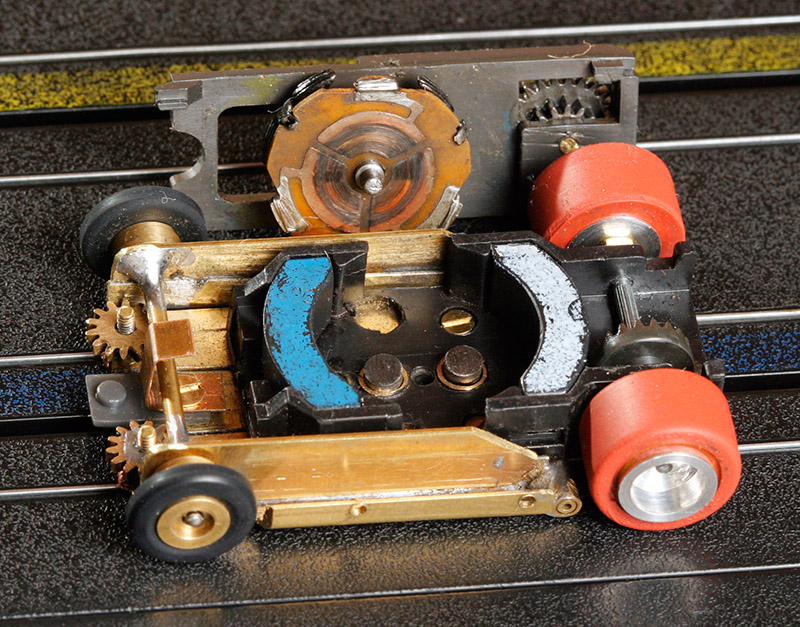

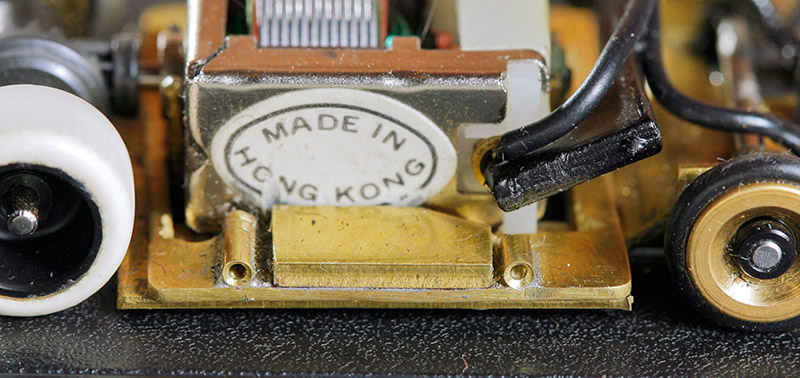

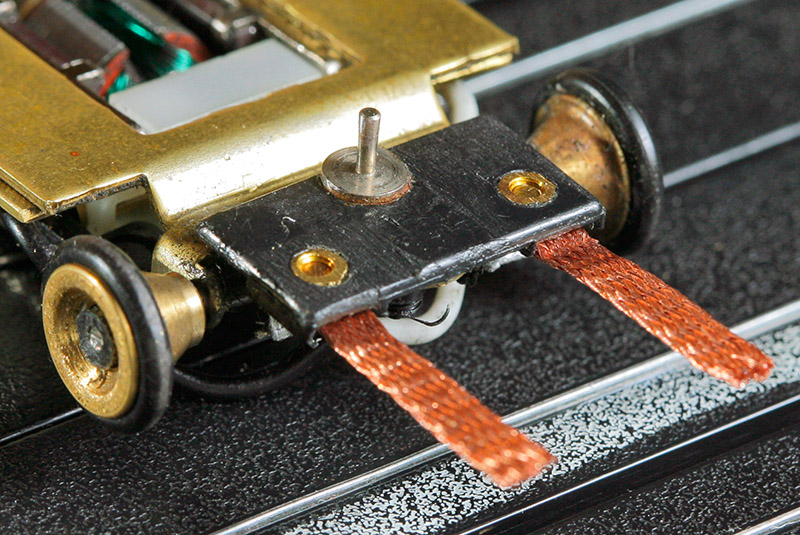

This is my first attempt at a chassis made purely from scratch. My goal was

to make it as simple and easy to service as possible. I

also wanted the ability to use and swap out currently available interchangeable

parts. As you can see it's pretty straightforward. The

can motor and 7/22 gearset are stock from a Tomy Turbo chassis. The motor is

wedged between the axle assembly and a brass shim and held in

place with a copper band made from two Aurora chassis bands soldered together.

It wraps over the motor and clips into notches cut into the

.035 brass pan making it easy to remove. The front end is a standard brass independent

JW T-Jet set mounted to a soldered-on hollow brass

axle. It accepts wheels held in place either with a nylon collar as shown or

with pins. Again, I wanted the pickups to be easily and

quickly serviceable. I also wanted a lexan body hinged at the front Super II

style for easy access. The black plastic piece from a Twinn K

TK004 AFX weight set is used for the body mount and pickup assembly. Two small

pieces of brass stock are glued in place to fill the gap on

the underside of the plastic piece, then covered in black electrical tape with

two strips cut from X-Traction pickups glued underneath. The

assembly is held in place by a #72 brass screw mounted as a stud from the underside

of the chassis with a lock nut. The pickups, made from

5/32" desoldering braid, are held in place when the nut is tightened down

over the assembly. The X-Traction strips make the electrical

contact between the pickups and motor when the assembly is torqued down. I fashioned

a shaker plate/body mount from angled brass stock and

steel wire that fit into the Twinn K bracket up front. As I was interested to

test the chassis right away I simply soldered the pickup

wires to the motor but now plan on modifying them with eyelets and screws in

the endbell for easy removal. This chassis is amazingly well

balanced with great handling and a lot of speed. On my 50' home track it beat

the AFX + Quadralam chassis I won the brass wars with last year

by a full second.

Parts:

Riggen Chassis shaker weight...

Guide Flag custom...

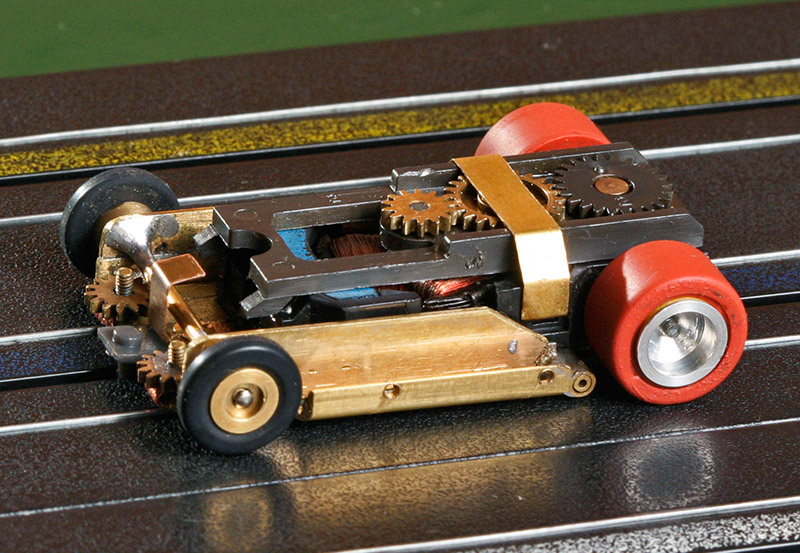

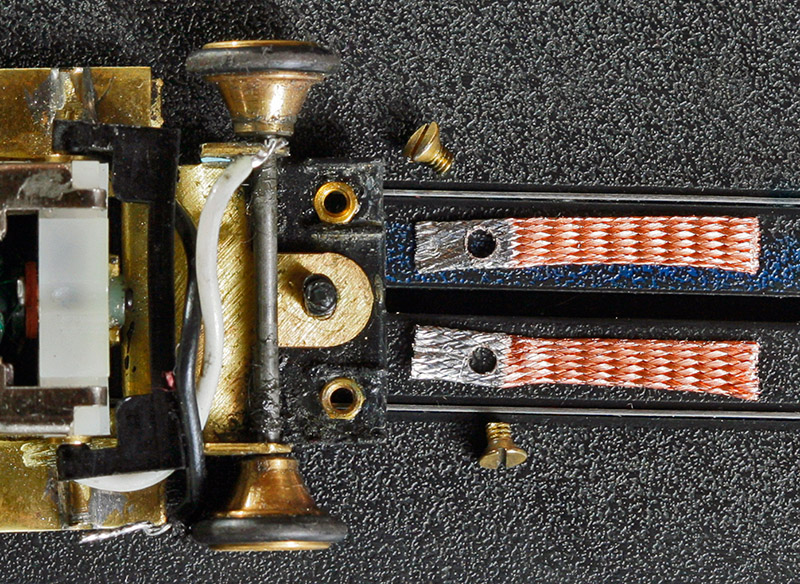

Scrach Built Pan Car:

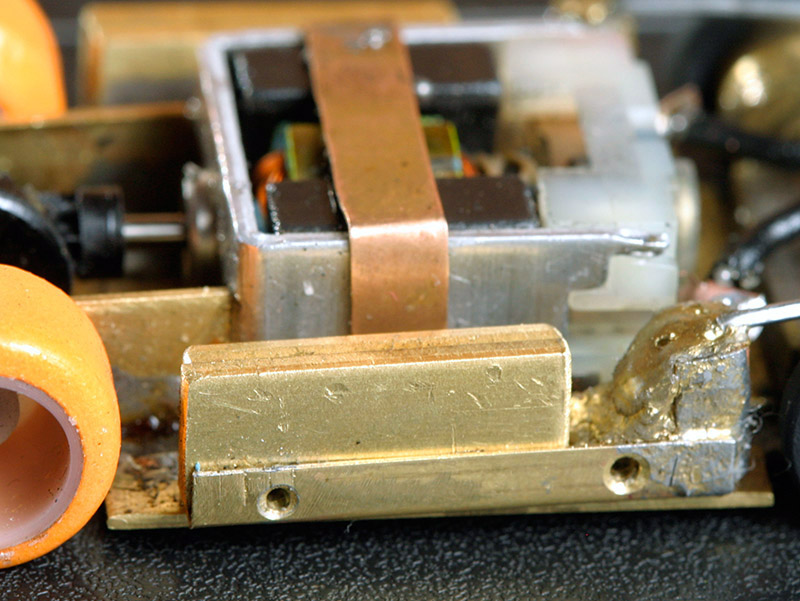

This is built off a standard AFX chassis. I wanted to replicate the full .035

TCP brass pan on one of my other chassis but with a little

less weight and, most importantly, a similar quick and easy way to replace the

wipers. The .025 brass pan is completely divided into two

sections which are both "hot" and carry current to the motor. At the

front I fashioned brackets from .070 brass stock which are soldered in

place and tapped with #80 screws. I use 5/32" desoldering braid for pickups

slightly tinned on both ends which are held in place with the

set screws. On the top side of the pan is a shaker bracket made from .070 brass

stock, drilled on the sides to accept a pinned lexan body,

and held in place with wire threaded through the front "short" axle

holes. It's finished off using a brass JW AFX front end and Wizzard

.460 LAW's with a Super II crown gear. The chassis is very well balanced and

handles beautifully.