RiggenHo Model Racing

Assembly Instructions Series 1000-2000

Introduction

Your RiggenHO chassis is very easy to assemble. The chassis was designed in

the 1970’s to be a very simple, straightforward high performance race

car. The advantages of this chassis versus its vintage competition was the very

low center of gravity and the ease with which professional hop up parts such

as wheels, gears, motors and tires could be interchanged and tweaked. These

features hold true today allowing you to prepare a fast, sticky, competitive

race car using contemporary technology.

A well-built chassis can be completed in about 20 minutes. To maximize your cars performance, track testing is very important. Consider your chassis as a tuning base for experimentation to match your chassis with your track and unique driving style!

Please Read The Instructions First. Track and racer tested Hop Up Tips are included within these instructions.

Feel free to contact us for any questions or to provide feedback!

Special Tools required for

assembly:

Your chassis can be assembled with basic hobby tools, but there are some special

requirements to do a professional job.

A gear press is required to install the crown gear on the axle. The RiggenHO chassis does not use a snap in axle/rear set up. The crown gear must be installed on the axle and in the chassis at the same time.

Light pressure adhesive such as (purple) Loctite is helpful to secure the rear “press-on” aluminum wheels. If you intend to use a different rear wheel set up such as screw on wheels or a Delrin hub set up, adhesive will not be required.

A sharp reamer or small drill bits are useful for enlarging guide flag hole on chassis and for body fit.

Preparation:

Confirm you have all the required parts. The stock RiggenHO parts are listed

below but there are many hop up and replacement options such as gear sets and

wheels. Assembly goes smoothly when all the required parts are in hand before

assembly begins. Gear mesh should be tested prior to final assembly especially

with press on wheels. To do this properly, you need to make sure the motor is

operating properly. Test the motor before you begin assembly.

You may decide to de-burr and polish chassis for appearance and/or performance. If your race rules allow, you may decide to drill or further modify the chassis. Chassis modifications are recommended before assembly (or most likely re-assembly).

The guide flag hole is very tight.

Use a drill bit or reamer to slightly enlarge the hole without bending angle

of the front of chassis so that the guide flag rotates freely when inserted

through the hole.

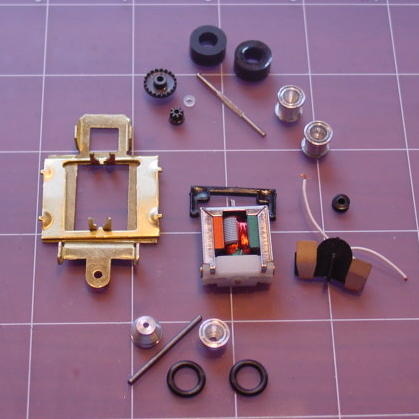

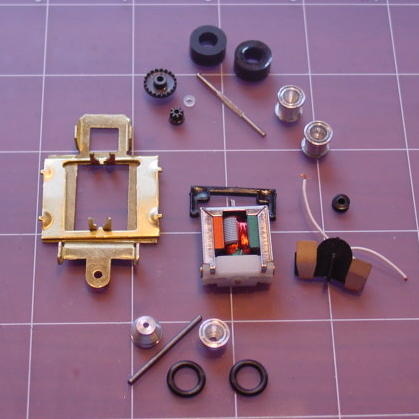

Parts List:

--2 piece brass chassis (chassis and shaker plate)--motor, guide flag, gear

set, plastic spacer, retainer pin and retainer clip

--rear axle, wheels and tires

--front axle, wheels and tires

--body

Crown Gear Assembly

Gear mesh is critical for maximum performance of your RiggenHO chassis. The

RiggenHO chassis does not use a snap in rear end set up. You must install the

crown gear on the axle and through the chassis at the same time.

Holding the chassis upside down, insert the rear axle through the right side axle hole and slip the crown gear onto the axle with the teeth facing right, followed by the spacer. Different gears may or may not require spacers.

With the gear and spacer in place, continue to slide the axle through the chassis and into the opposite axle hole, and then insert the assembly into a gear press.

Screw in the gear press (according to manufacturer instructions) until the axle (not the gear) is spaced evenly between the rear uprights and the ends of the axle are equal distances from the edges of the chassis on both sides.

NOTE: ***If you are going to be

using pressure fit front wheels, install these on the chassis BEFORE you install

the Motor and Guide Flag Assembly

Prepare and Assemble Motor with Guide Flag Assembly

Note the proper orientation of parts to be prepared and assembled in this step. The guide flag wires are crossed which is desirable (this provides some "tension" on the guide flag and gently limits swivel).

Install the pinion gear onto the pinion shaft. For most plastic pinion gears, this can be done by hand. For brass or aluminum gears, a pinion gear press is recommended.

Insert the stripped ends of each guide flag lead wire into the brush tubes on the sides of the HT-50 can motor. The wires do not generally need to be stripped further but they must be fully inserted into the tubes.

Install the wire retainer clip onto the motor, securing the wires into the brush tubes.

The shaker plate can now be placed on the chassis with the motor retainer cutouts in front and the domes of the body mounting nibs “up”.

Snap the motor onto the chassis between the chassis motor retainer uprights. The motor fits snugly and should not bend the uprights.

Motor magnets should have the colors facing up and the guide flag lead wires should be crossed.

Install the guide flag into the guide flag retainer hole from underneath and secure with the retainer pin.

Check that the guide flag swivels smoothly with just enough rotation, and check

for proper gear mesh between the motor and the crown gear. The gear should turn

smoothly in both directions with no binding.

Do not continue until you have checked the gear mesh by applying power to the pick ups!

Recommended Hop Ups: Many contemporary

gear sets will work with your RiggenHO chassis. Choose the one that best fits

your driving style and track. As a general rule of thumb, low gear ratios offer

more top end speed and higher ratios offer more "punch" and braking.

For short and twisty tracks, experiment with a 25/7 gear set (This is what Tomy

SuperG+ uses). Choose the 20/8 gear set for pro tracks with 12 ft (or greater)

straights (which is stock on the AFX G+).

Install Rear Wheels and Tires

Stock RiggenHO Pressure Fit Rears are custom made from aluminum and weigh 1.5

grams without tires and 2.4 grams with stock tires.

A proper wheel press can be used to install the rear rims on the axle but most will simply fit on the axle with light turning pressure by hand. Secure the gear with your finger to prevent the gear from slipping on the axle while you fit the wheel. If the wheel fits too loosely, use a small dab of light pressure adhesive such as Loctite (purple) to secure wheel to axle. Make sure you do not get any Loctite near the axle hole on the chassis!

Completed chassis width is 1 5/16th inches.

Recommended Hop Up: RiggenHO Double Flanged Screw ON Wheels. These are machined from aluminum and screw on to an .080 thread on the axle. These are spec’d to match the RiggenHO chassis and tire.

Recommended Hop Up: RiggenHO Set Screw Wheels. These are machined from aluminum

and use grub screws to secure the wheel onto the axle. RiggenHO stocks a Champion

vintage set screw wheel, but others such as Super2 wheels can be used.

Other rear wheel set ups can also be used such as vintage AFX hubs, vintage TycoPro hubs and even new bonded silicon sponges on Delrin hubs. Refer to manufacturers guidelines. See the RiggenHO.com website for more examples in the “Readers Rides” section.

RiggenHO stock rear tires are “No-Tear”

silicon slip on style. These fit tightly on RiggenHO stock rims and are very

durable. They measure .436 on the wheel. Racers have used various sizes from

.432 all the way up to .450 depending upon body style.

Install Front Wheels and Tires

Stock RiggenHO Pressure Fit Fronts are custom made from aluminum and weigh 1.3

grams. The front axle is hardened steel. Install wheels using a proper wheel

press with tapered insert and tap lightly, checking frequently to make sure

you don’t “over-press”. Protect your wheel with a cloth or

small piece of rubber while tapping to prevent scratching the wheels.

O ring front tires simply stretch around the front wheel and fit in the groove for a tight fit.

Recommended Hop Up: RiggenHO Brass Inde Fronts 3.3. These are custom made for RiggenHO and weigh 3.3 grams. These install with included Delrin retainers. For those that prefer a heavier front. Look great too!

Other front end set ups can be used.

Refer to manufacturers guidelines. See the RiggenHO.com website for more examples

in the “Readers Rides” section.

Prepare and Install Body

Check your body fit against the shaker nibs. The nibs should protrude the body

in the pre-punched holes. The body should fit tightly. Fit should be low and

even. You may use a small reamer or drill bit to slightly enlarge these holes

for optimal fit but be careful not to make the holes too large to provide a

tight fit.

Check ground clearances at the front and back on a test track. Test wheel well clearance and trim slightly as needed. Other Lexan bodies may be used on your RiggenHO chassis. Check for proper width (1 5/16th”) and adequate motor clearance.

Advanced Builders: Use “pin tubes” to attach your preferred body. Tubes are generally applied on the shaker plate (the nibs are good indicators of placement, be consistent!) to allow for vibration dampening, but you may experiment with tubes applied directly to the chassis for a super low fit (check body heights!)

Final Prep and Guide Flag Adjustments

Your RiggenHO chassis should be considered a tuning base to match to your track

and unique driving style. The single most important adjustment you can make

to your car is the angle and bend of your wipers (or braids). Some drivers prefer

a flat alignment, other prefer a slight downward flare at the trailing end of

the wiper.

A light application of race oil at

the front end of the arm shaft as well as at the crown/pinion joint is recommended.

A lot of motor whine can be removed with this simple step!

Final Comments

Your RiggenHO chassis is designed to be very competitive yet very durable. We

urge you to experiment with different set ups to optimize performance for your

particular track. Additional products are under development.

Your feedback is very important to us. We strive to continually improve our product and many of our improvements are directly related to user feedback! Please contact us at riggenho

Information is updated frequently on our website. Please see www.riggenho.com for the latest information including more hop up tips, reader rides and new products.