(click images for larger)

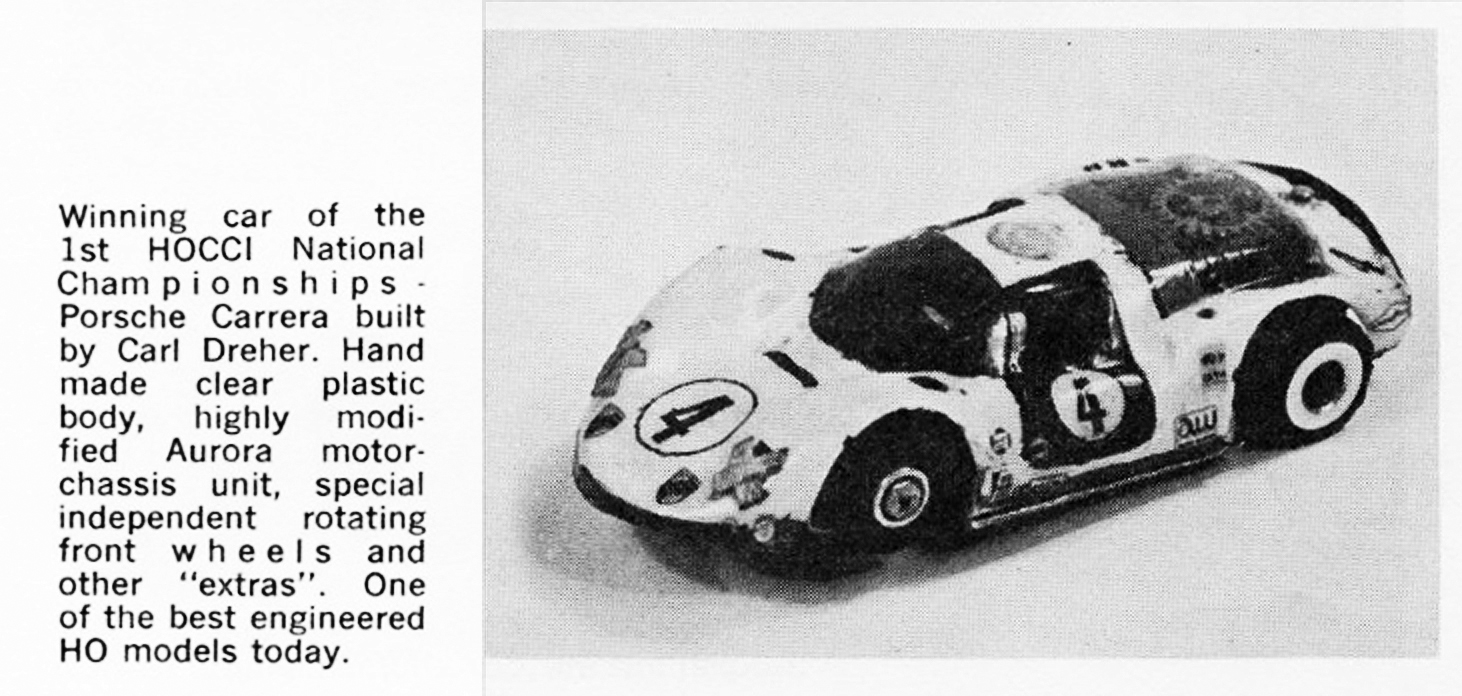

Items From the archive of Carl Dreher

February 2009

------------------------------------------------------------------------------

1968 Modified T Jet, Iso Pan experiments

"I'm attaching three photos of what was by far my most successful

HO racer,m circa 1968. It was built on a TJet chassis, of course.

What was innovative about

it can be seen on the bottom. There is a center pan, surrounded by an outer

perimeter pan that can move front/back/left/right about 3/32 inch. The body

attaches to this outer pan. The outer pan does not hinge at the front like designs

which came later in history. It is constrained to work in the same plane as

the inner pan. It has nil up/down freedom.

I experimented extensively on early designs to isolate the body from the

chassis. Those tests paid off well in terms of handling. Anything that allowed

the

car to absorb track vibrations and keep the tires on the road really helped.

I also tried allowing the entire pan to float, but this always proved

temperamental and too often resulted in the pan shorting against a high-spot

on a track. Then I hit on this idea of making the pan in two parts and letting

the

perimeter of the pan, with the body and balance weights, float. Took a long

time to make but it worked wonders. The result was a great handling car and

very

forgiving to drive.

The three holes on the bottom are there for quick maintenance during a

lane swap. I could give the armature and brushes a quick shot of lube. The center

pan

is insulated from the Pat Dennis brush

tubes by some thin tape.

Notice the amount of lead in front of the axle and on the leading edge

of the outriggers. I always biased my cars with weight on the front to keep

it in the

slot. There should also be a lead weight glued in behind the front axle, but

that seems to have gone missing.

The front axles slides back and forth, using Faller springs to center it.

The brush tube leads are soldered to the pickup shoes. I found a fresh pair

of shoes

could go a full race without replacement, thus the soldering."

------------------------------------------------------------------------------------------

More on how to set up a car:

The brush tube setup was taken from Pat Dennis' article in Car Model magazine.

I used K&S brass tubing (size? probably 5/32) and .015 for the end caps,

soldered them together and trimmed. The holes where the TJet brush spring arms

were enlarged so the tubes would fit and I put a dab of epoxy around them. The

old brush spring arms were removed, of course. The holes weren't just drilled

out... they were offset very slightly in the direction of rotation to give some

advance to the timing. Finally, some thin wire was run from the pickup shoes

to the sides of the tubes. I'm trying to remember what brush springs I used.

I

genrally used the Aurora pickup-shoe springs, but getting the right height was

critical. I remember spending a lot of time on the bench removing a tiny snippet

of coil, reassembling the motor, and running it, listening to the RPM. There

was a magic amount of pressure that gave good brush contact but not too much

friction. Eventually, I could do it by feel. I also tried the very flexible

brush tube springs that Faller used on their HO cars which had, stock a brush-tube

setup. As I recall, they worked very well.

Rewinds: As I recall, my best wind was 12.5 feet of #37. I was never able to

get a #36 wire wind to survive. It just drew too much current and would burn

up

brushes and eventually, itself, from the heat. I know some other guys were able

to make a #36 rewind work, and when they did, they were very fast.

Magnets: Sorry, don't remember much. I think I used the "hop up"

magnets Aurora sold. I never found any of the other after-market magnets to

be any advantage

or to last very long.

Funny thing about magnets and rewinds: There was a sweet-spot that matched

my driving style. I could build a killer fast motor with super strong magnets

and a

wild rewind but when backing off the throttle, a motor like that would cause

the car to stop suddenly from brush friction, dynamic braking and the strong

magnets. Motors like that also had a bit of hesitation on acceleration. My driving

style was much more of a "coast-through-turns" type, so I wanted motors

that were more forgiving.

Other things how I set up a car:

1. I always trimmed a sliver of material from the TJet chassis "ears"

that held the magnets in place, so the magnets would be closer to the armature

to reduce

the flux (air) gap. Then I put a piece of shim stock (steel) behind each magnet

to hold it in place.

2. Front axles were 1/16 brass tubing with Faller springs to center the axle.

The brass axle risked being bent in a crash but I almost never had that happen

in a race and, being brass, it was easy to solder a brass washer on the end

to keep the wheel on. Some guys tried to put bent pins in a brass tube to keep

the

wheel on, but I saw too many of those come loose. I usually turned the stock

front Aurora tires down a bit and gave them a coating of clear nail polish,

then

trimmed the length of the guide pin for the best clearance. Some tracks weren't

built too carefully and so it wasn't unusual to need to trim the guide a bit

more, or in the opposite case, put larger front tires on the hub to gain ground

clearance for a bumpy track.

3. I always used a stock Aurora guide pin. Super reliable. I tried every kind

of guide flag and even built some of my own and rejected them for one very

specific reason: In a race, if you come off, you are at the mercy of the turn-marshal.

Even a ham-fisted turn-marshal could slam a guide-pin equipped car back

into the slot, but a guide shoe took a lot longer and was subject to being broken

off by a guy who was in a hurry.

4. I always used the long-wheelbase axle hole in the chassis. That gave the best handling.

5. I always soldered the first gear to the armature, since I had seen too many

come loose in a race. I think I normally soldered the rear pinion shaft to the

rear gear-plate gear. Never soldered the pinion gear to the shaft... never had

a problem there.

6. I always used the stock pinion/crown gears because I found the stock ratio

(as opposed to Aurora's "hop up kit" ratio) much more responsive.

See my previous

comments on driving style. I *think* some of the guys using a #36 rewinds were

trying the higher hop-up kit gearing because they could pull that high ratio

with the more powerful motor. Not totally sure about that. We were all rather

secretive.

7. I never mentioned the type of brushes I used. The Faller brushes, with the

nipple on the bottom that were designed for brush-tube springs, were WAY better

than stock Aurora or any of the after-market brushes, including the so-called

"silver" brushes. The Faller brushes seemed to have a low coefficient

of friction

as well as good electrical properties. I used to buy all the Faller parts I

could through the Hobby House in Monroe LA.

8. Tires and hubs: I used LaGanke (sp?) hubs exclusively, and epoxied sponge

rubber tires on them. (I don't remember where I got the black sponge donuts.)

Then I'd turn them to size. I do remember doing a lot of "blue printing"

in the sense that there was considerable width variation in a batch of blank

donuts,

and I'd get a couple dozen sets and then find the widest that were still within

the rulebook. By the way, when I met Pat Dennis for dinner, he also mentioned

Tim Laganke, and what an honest guy he was. One of the few guys you could trust

not to rip you off and would pay for rights to your ideas. Wonder where he is

-----------------------------------------------------------------------------------------------------------

June 1970 Car Model Magazine: Carl Dreher Tames the Tycopro

This appears to be the magazine car and photo "mule"......

(click for larger)

here is page 2 and

page 3

Auto World Speed Secrets.....

full article on these links....page

1 page

2 page

3 page

4 page

5 page

6

About this body: "Speed Secrets" body....Ah the Porshe

body! You won't find any of those unless you can find someone who bought them

from me when I was selling them mail order. I made those on a

Mattel Vac-U-Form machine. The basis for the body was a Lindburgh (sp?) plastic

Porsche 906 (I think) kit. I widened it, raised the rear window to clear the

gears at the back of the TJet chassis and enlarged the front wheel wells so

a pickup shoe at full up-position would clear the body. Then I made a single

Vac-U-Form body over that model and poured a plaster master from that female

mold. From there on, I could make as many as I wanted. The hard part was finding

the clear-plastic for the Vac-U-Form. You had to buy a big stack of that Mattel

plastic (they were sold in packets of mixed colors) to get a couple of pieces

of clear. For some reason, the clear held up better to the heat given off by

the slot car, and of course, you could paint it inside to look nice. I tried

making bodies from the colored plastic they had, thinking I could save some

weight by not having to paint it...yes, I was a fanatic about weight...but the

plastic always melted from the motor heat.

---------------------------------------------------------------------------------------

September 1973 Car Model Magazine

AFX build....page 1 page 2 page 3

---------------------------------------------------------------------------------------

Various Photos from the C Dreher lot purchased on ebay....

here are pics of another R-M chassis...anyone know more about these? (Collection

John F)

Full brass pan

That photo (BELOW) is of a chassis for an Indy/F1 car. Notice the pan has no outriggers, and notice the silly rollbar and the remains of a driver cockpit. The HOPRA/HOCCI rules were real specific about how wide the body could be in the class. My cars were OK in the class, but weren't my best. GTs were always my favorites.

More detail on this indy build...