Improved RiggenHO guide flag--by AJ Hoyt

February, 2009

Ron,

I have included two concepts that I developed shortly after Walt Pierce placed a club-sized order with you on behalf of the FRHO racers here in CO. None of us were happy with the guide flag and we all modified the cars to adopt some form of quick-change stationary pick-up system and guide pin.

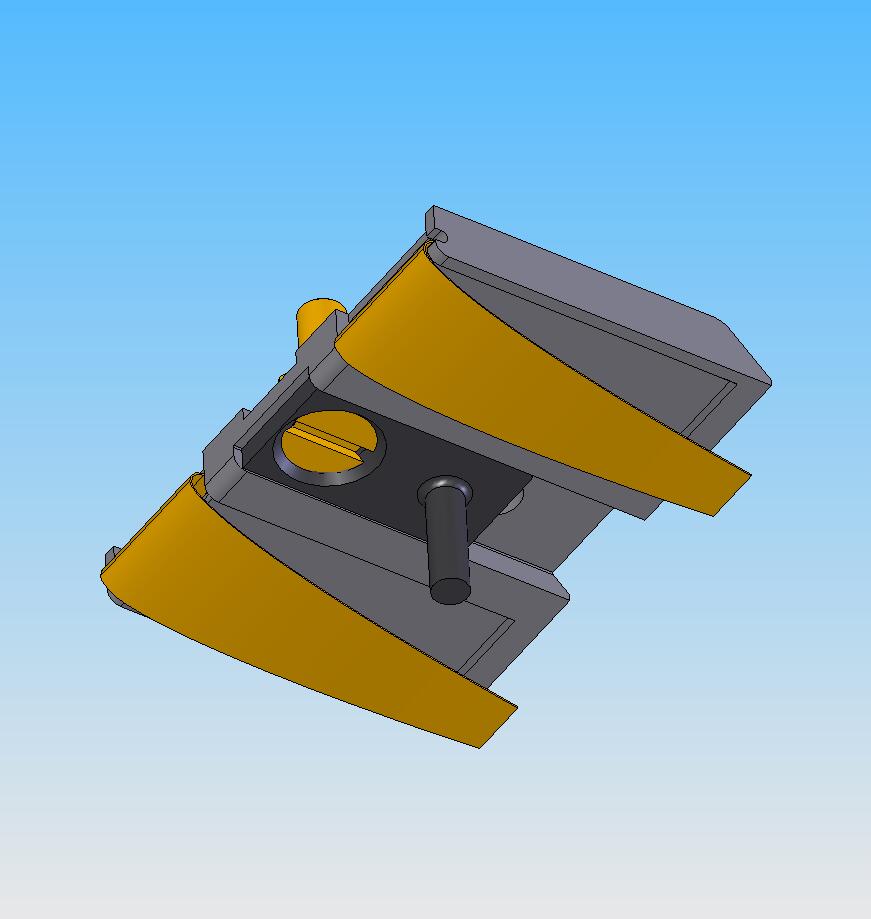

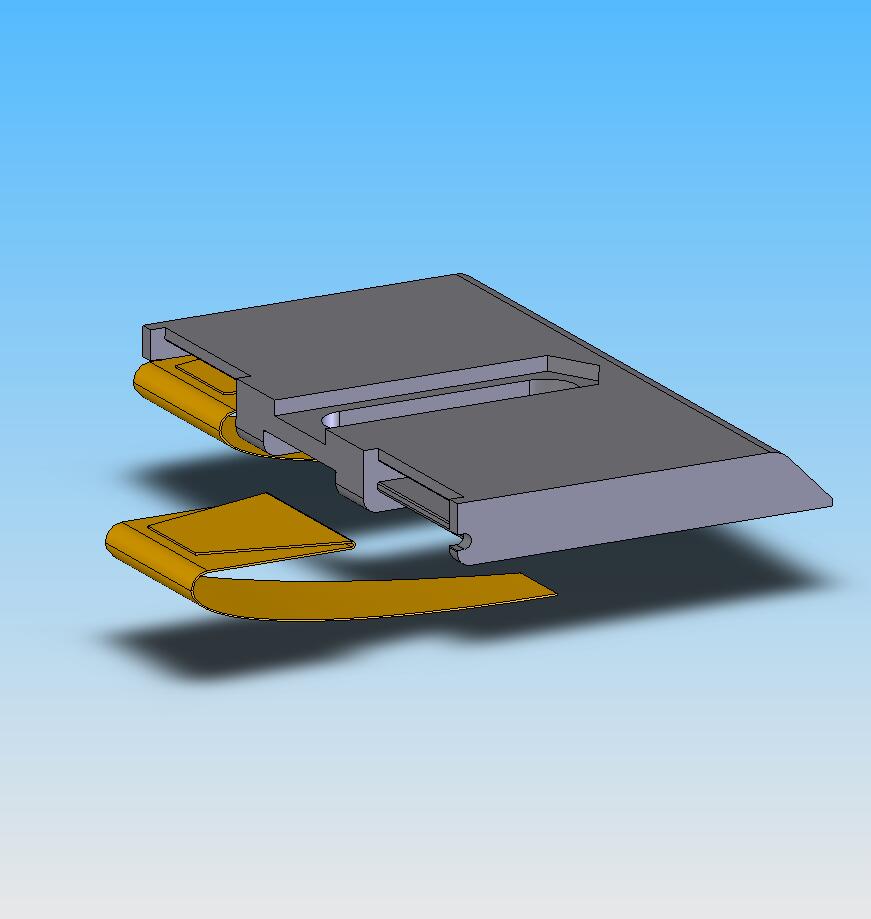

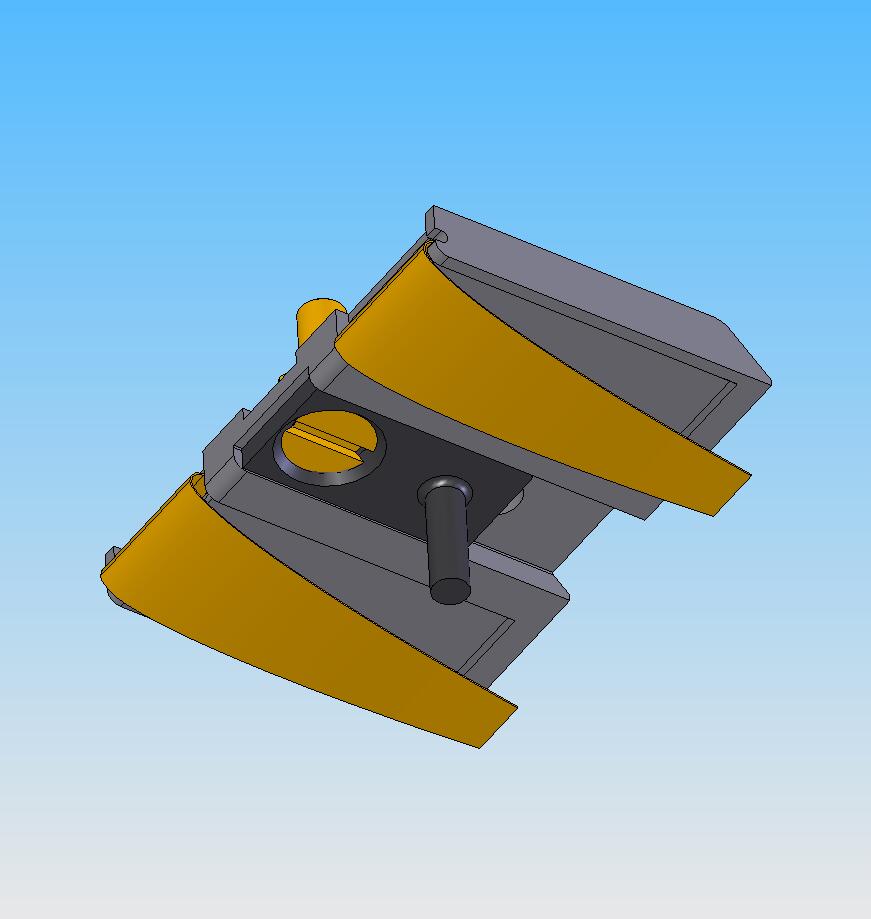

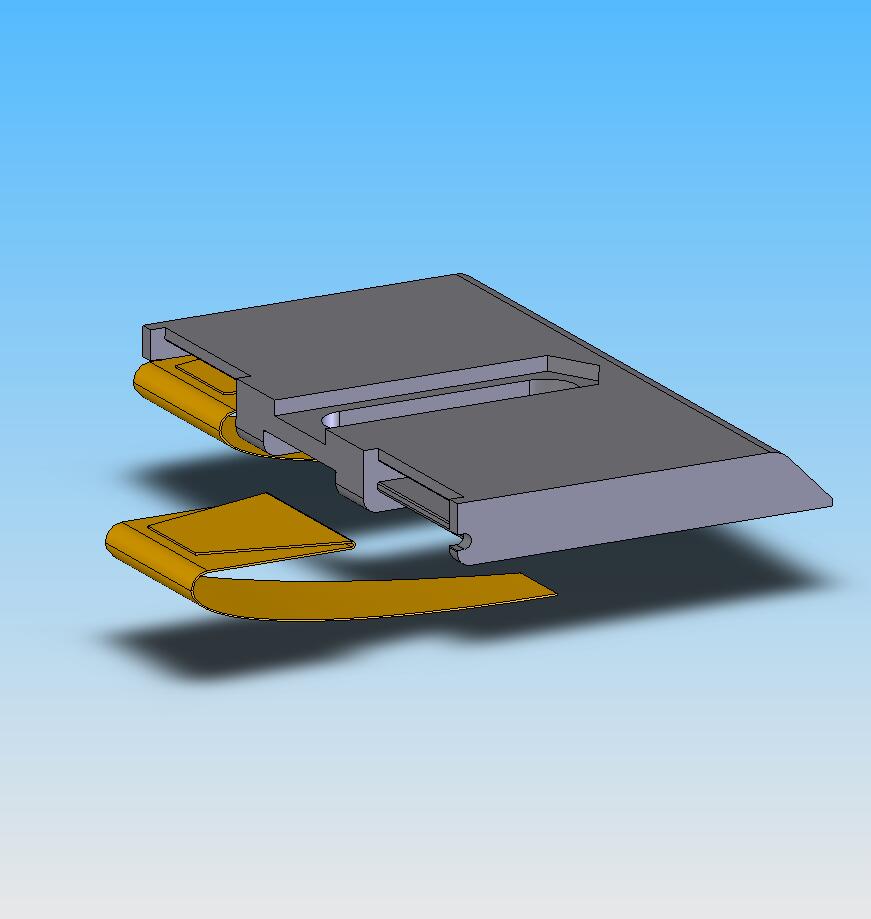

The colors imply the materials so the major component is designed to be a machinable plastic part with a formed .003 brass pickup holder that is bonded into the channel with epoxy. In the exploded view, you can see that there is another brass component that slips in with the pickup and has a rearward facing surface to solder the wire end to. This is very similar to the long-accepted system used in 1/24 racing.

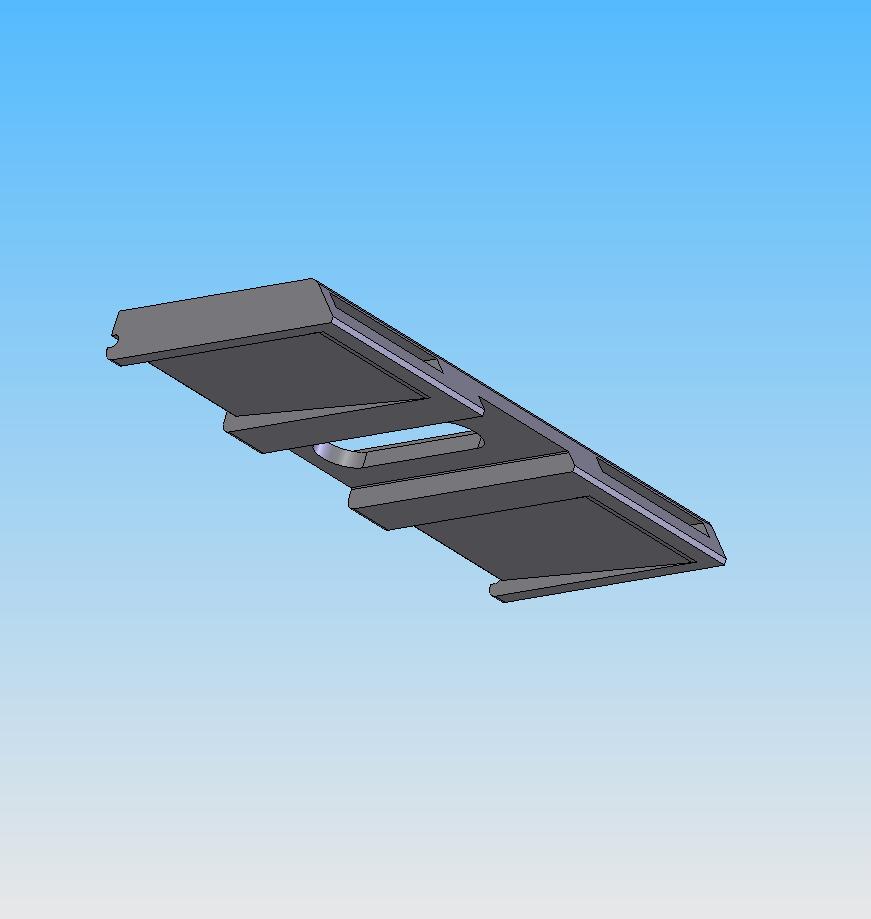

I have even included the angle at the rear of the part that nestles into the up-formed angle on the Riggen chassis stamping for locating the part. It would be a simple matter to affix it using the normal guide flag tongue.

A really trick feature I incorporated is a slot for the position-adjustable Aurora T-jet guide pin. The flats of the holding nut are restrained from rotating by the sides of the nut channel. This allows the racer to "tune" the guide pin distance from the rear axle fore-and-aft (also, in relation to the contact point of the pickups). The guide pin location was a subject of much debate back in the '70's HOPRA days with an optimum position usually dictated by the track. When we raced six lane tracks, the shorter distance (of the pin from the rear axle) really seemed to work better in the tight turns of the gutter lanes while the longer distances really seemed to help the handling and smoothness in the middle lanes. Of course, our guide pins were rigidly located in a position that we deemed was the best compromise for the day.

If I, as a racer, had an opportunity to test at different distances and believe this for certain. I believe I might now be inclined to change the position just a bit during a race just before entering the gutter lanes, particularly if I could change it in only about 5 to 10 seconds!

I incorporated a bit of a tapered channel where the pick-up wiper lies. I strongly felt that this promoted a "softer" more linear acting spring force that was still able to maintain a sufficient persistent force to contact the rail. Obviously, a "softer" pickup tended to not push the nose out of the slot, promoting better handling.

This design also allows racers to experiment with different pickup trimmed shapes. The one I showed in the images reflects my personal paradigms (everyone, again, seemed to have their own opinions back in the day) that were particularly successful when we raced the "Brass Wars" class a few years ago on modern tracks.

One thing that I found interesting a few years ago was that I did not have a source of phosphorus bronze .003 thick 1/2 spring temper, like we used to get from Marty "The Bronze Man" Thalison. I used .0025 thick brass (I think this is a metric mill run size), which was thinner than even the .003 that you can still get in a brass shim pack at an K&S display in most hobby stores (when they are in stock). This "goldilocks" tried the K&S .002 thick and it was too thin; the I tried the .003 brass and it was too thick; the .0025 brass seemed "just right".

Even more stunning was that the 0.0025 thick brass pickups lasted at least two race dates with minimal wear (there was always a "hot side" that wore more than the other, just like 1/24 braid still tends to).

Back in the day, it was critical to get our "perfectly tweaked" set of pickups to last a Semi AND the Main; any racer will tell you that a good day demanded that that primo set last for both! Thrashing a new set of pickups between races was usually not fun because the ALWAYS required additional tweaking.

These concepts allow you to make many sets that have all been "pre-tweaked" to your preferences and simply swap the pickups when they wear out with predictable results.

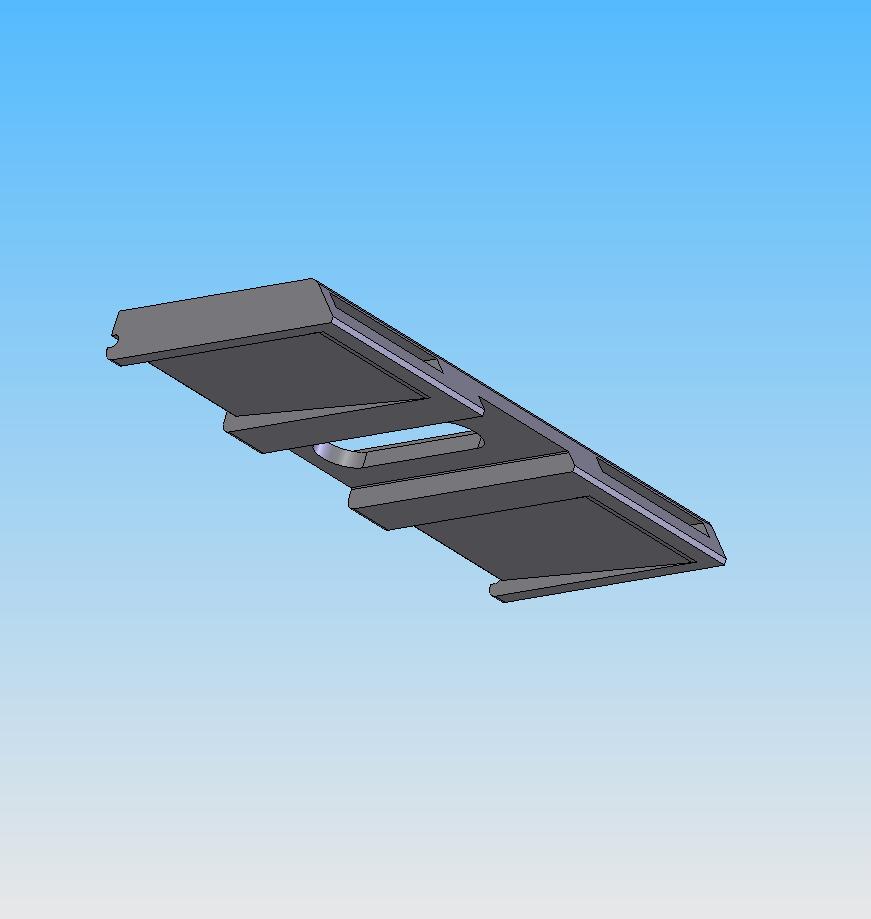

Ron, I am sharing these images ONLY with you and Keith. Please feel free to use or ignore them at your pleasure. The first concept is designed to be a machined part with the formed brass pickup holders bonded in. The second concept is intended to be a simple molded part.

I fully understand that this departs from the original Riggen concept but it is, I believe, a significant improvement on where the Riggen-derived cars had settled before the A/FX pan cars took over.

I also understand that, if you were to offer this part, it would curtail recurring sales of the classic guide flag but I think it may start another wave of racing class that affords some "tweakability" for the racer that is so inclined. And, I have to admit it, the Riggen-derived cars are a BLAST to drive and race plus they sound so darned cool. User-made pickups offers a new level of affordability for a part that wears out.

Keith, you are a viable person to peer-review this concept - which includes adding criticism or suggesting additional features. I am still in possession of the SolidWorks CAD files that these images were created from.

Best regards,

AJ