TycoPro Museum

Motors....

By way of introduction, here is a section from a Magazine scan from June 1968....(click

here for entire

page)

Small in-line motor..."This project consists of an Alnico magnet which was bored to allow the armature to pass through the magnet. the concept was to place the magnet weight at the rear. The arrival of the ST-02 halted the project...."

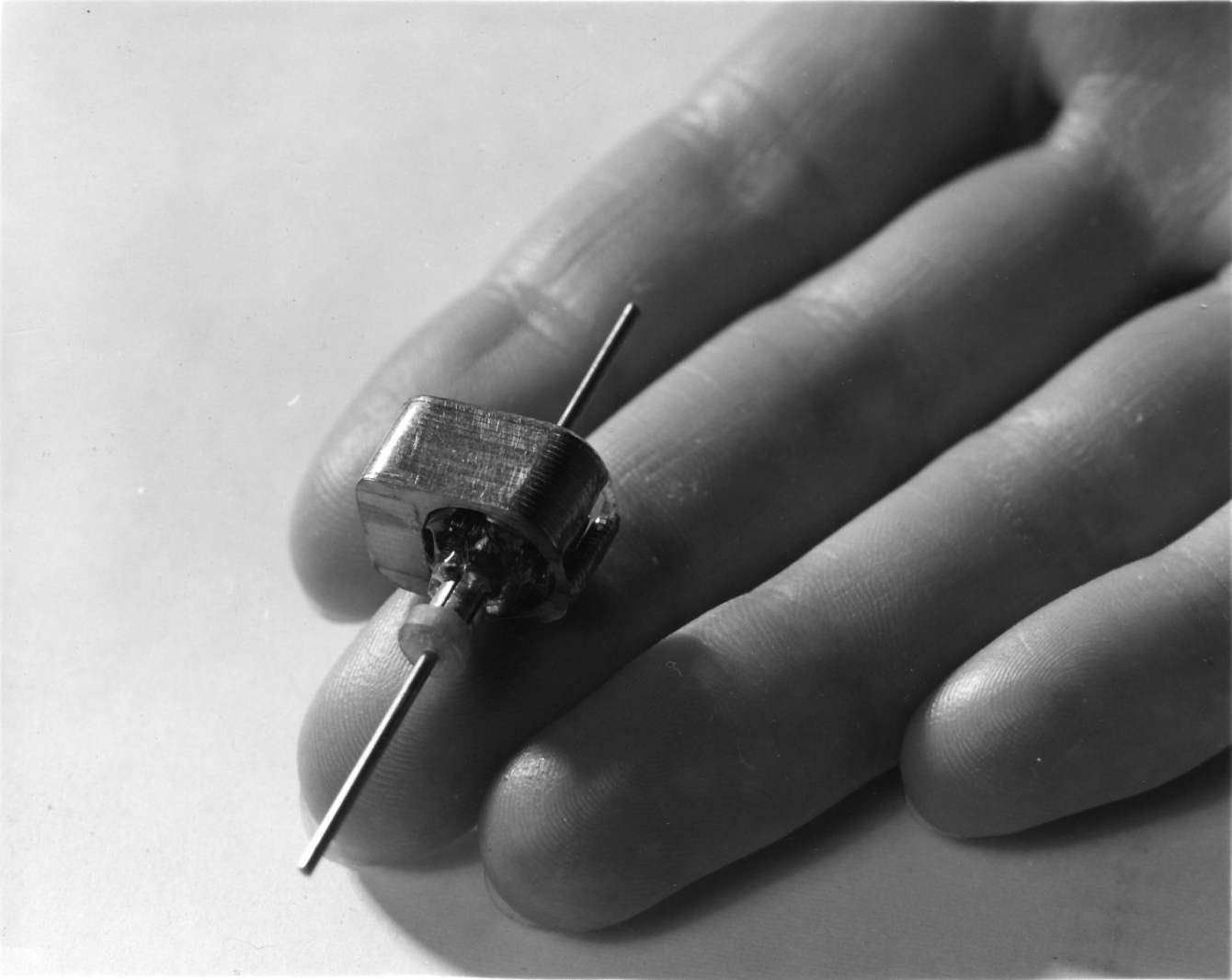

Pitman DC 85 Style Motor...."This project was an exercise in miniaturization. Note that the commutator features the PC board centrifugal locking rings. The ST-02 also made this obsolete."

The laminated pole pieces were steel strip epoxied together and machined to shape. I vividly remember how carefully I had to machine these to prevent excess heating which would cause epoxy failure - and laminates flying.

Question: "The mini Pitman is wild...can you retell the concept of centrifugal locking rings please, I dont recall and dont have it in my notes...?"

Answer: "Most early motors utilized molded Nylon for the commutators.

When we started rewinding (back in the dark ages of slot racing), the heat softened

the Nylon until the copper segments just flew out with the centrifugal forces,

resulting in a rat's nest of windings and other catastrophic events. So I designed

a washer shaped ring from silica-glass PC board material. I usually put two

on each - one at the solder end and the other at the outer end retained with

high-temp epoxy. Worked beautifully, no more explosions."

Crown gear...."this is the second crown gear produced for the prototype. The first is still in the original chassis. Also included with this gear is the original pinion gear modified from the friction toy as discussed..."